I recently went to a discussion at The Building Centre ‘We Made 2012 – Temporary structures and Demountability’ where the success of the London strategy and potential lessons for other cities were discussed. This prompted me to write about the Shooting Venue in Woolwich where I was involved in quality control for The Olympic Delivery Authority.

The modular architecture that formed the basis for the Olympic Games started in the Rock and Roll days of large scale touring by big bands such as Bruce Springsteen and The Rolling Stones. Large temporary venues were needed to be erected for vast crowds quickly. These temporary construction systems were adapted over time and were used in a variety of ways during the London 2012 Olympic Games.

The London 2012 Shooting Venue was designed by Magma Architects; Mott McDonald and Momentum. The venue consisted of a 50/10m shooting range; a 25m shooting range; a Finals shooting range and Shotgun and archery range. These three pavilions formed a collection of colourful tents scattered around Woolwich Common and together they formed a shooting and archery campus.

The pavilions were essentially large steel frames with a fabric skin around them. The range (field of play) was enclosed in a plywood perimeter fixed to a steel frame. Most parts of the pavilions could be easily removed and reused. The piles for the venue were all made from recycled gas pipes driven into the ground, easy to recycle once the Games were over. The structure for the three pavilions used rental components (meaning exactly that, they were rented and not purchased) which determined the structural layout of the pavilions.

The buildings were clad in 18,000 square metres of phthalate-free PVC membrane and head rings were used to tension the fabric. Head rings are large circular steel structures that push out the membrane fabric (keeping it in tension) to create a roofscape and a façade of protruding ‘flutes’. Head rings vary in height and slant according to their positions which create the undulating roof scape. The cleaver bit is where the head rings double as ventilation zones, the fresh air coming in through the façade and being extracted at high level through the roof using buoyancy (hot air rises), a nice combination of an architectural idea and a practical solution for ventilation.

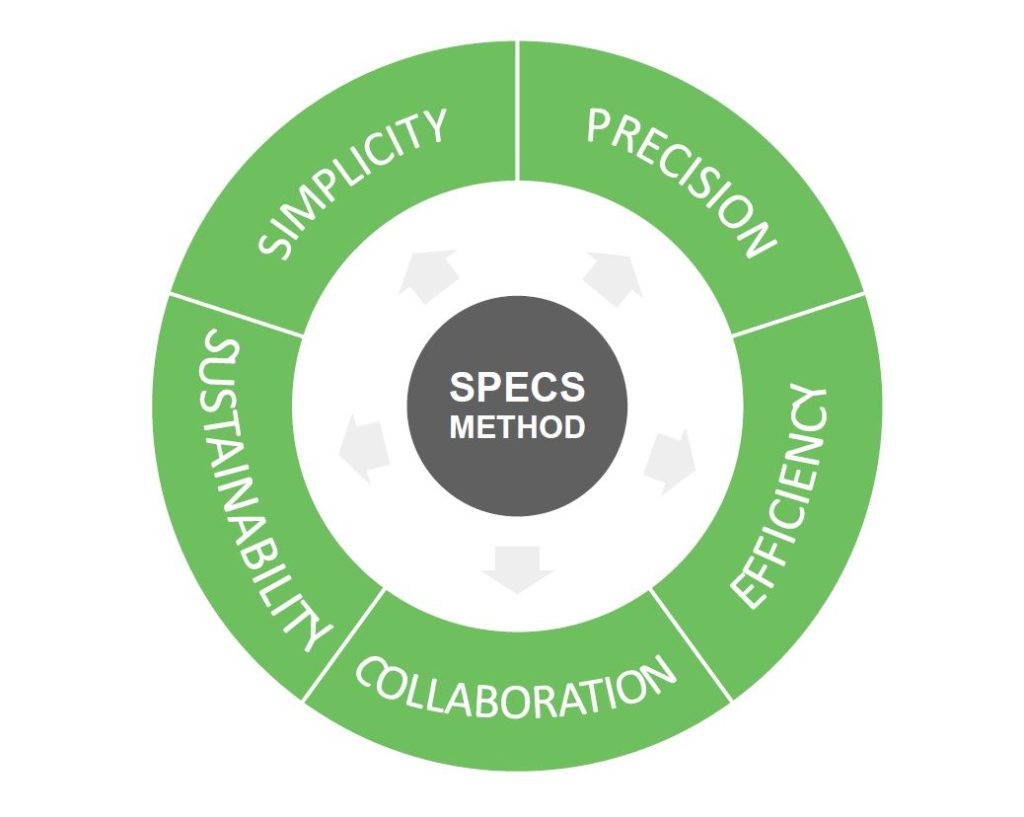

This project was a great example of where collaboration between a manufacturer who is an expert using rental equipment, and a designer who has a vision of how a venue can be celebrated and how it should sit in the landscape, can come together to create a design that can be reused and recycled. Parts of this venue are to be reused for the Commonwealth games in Glasgow. The manufacturers call this ‘precycling’ where the reuse of all of the equipment is carefully planned. When you ‘precycle’ you plan the second and third uses of the equipment during the initial design phase. I believe this new technology can be more widely used; in different locations and climates and for different uses such as disaster relief (post earthquake structures), classrooms or small stadia for schools, arts and sports events.

The legacy of the project is that architects and manufacturers have shown how these ‘precycled’ rental systems can be the future for large scale sporting events. In the future, to reduce the massive cost to host countries of staging the Olympic Games and World Cups, it may make more sense if some of the venues are ‘packed up’ and transported to the next country ready to be reassembled. I cannot think of anything more sustainable than that.